I often have a few crap vacuums lying around that I get given. They come in handy sometimes too, an old colleague and freind of mine is moving out of her parents house, and asked me if I had anything. She has bare floorboards, so I didnt think a DC07 would be very good, so I said I'd have a look and see what I had.

I found a Bush bagless cleaner in the shed, but upon turning it on it seemed the motor had killed itself, so I had another rummage and found this:

I remember getting this, a lady posted up on a local selling site asking if anyone wanted 2 free hoovers, and 4 people tagged me in the post. Got a nice DC04 Absolute+, which is long sold, and this. It's idential in pretty much every way to a Vax Centrix 3 I had a few years ago, which was shite tbh, but she wanted a cheap vac, a cheap vac she shall get!

Dustbin out

5 screws and one security torx screw and the top housing lifts off

Was held on by 2 cables going to bits on the lid

Which connected on alternate sides

The post motor filter and housing fell out at this point too

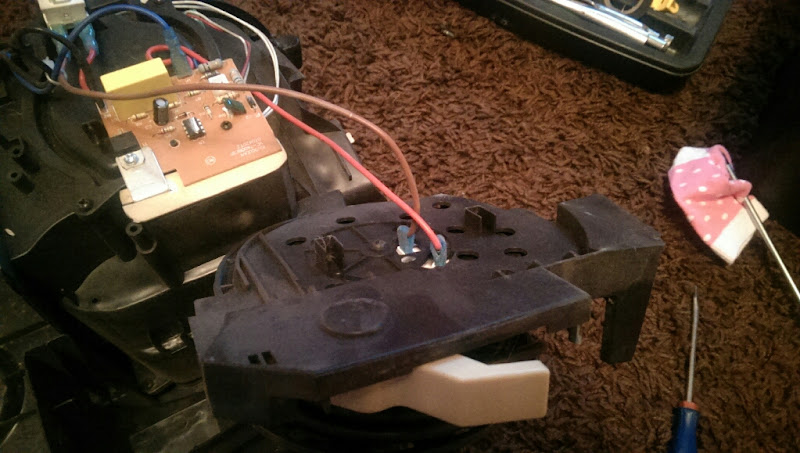

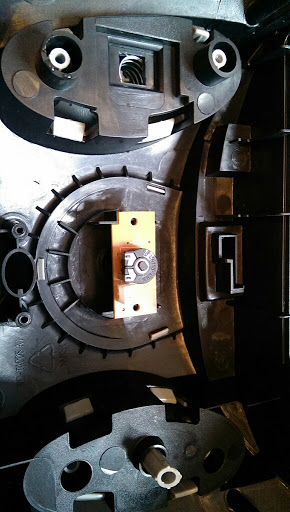

Under the lid was the speed control board and led light for blockages

An internal chassis unscrewed

There was a roller to help guide the cable out

Speed control module

and the LED board

The lens for the led pops out from underneath

Speed control knob and trim pops out

The pedals pop out now

the 2 blingy chrome trimz unclip from the sides

The front hose entry trim unscrews and the seal is removed

the under handle trim unscrews

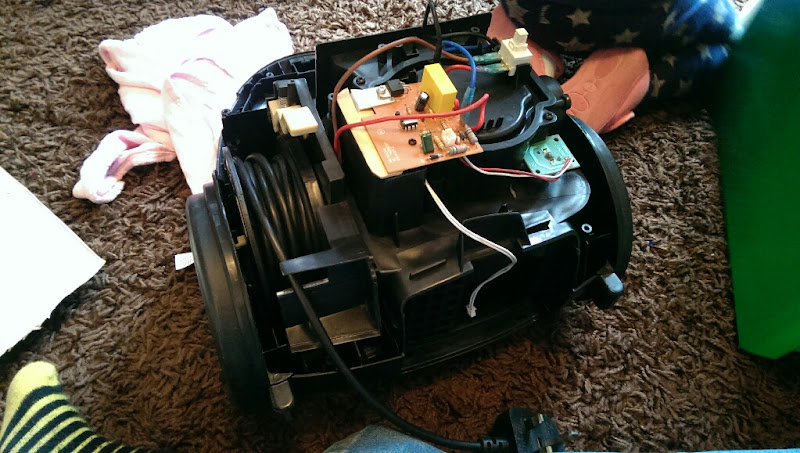

Onto the main part of the machine now!

The cord rewind mechanism lifts out

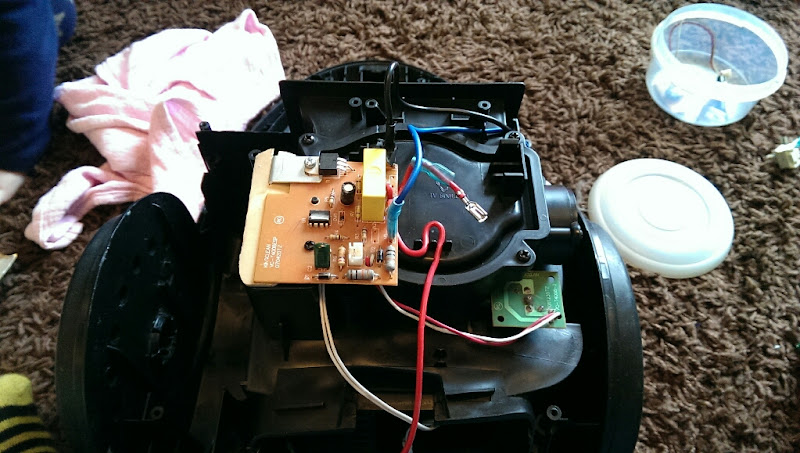

Onto the electronics now

Power switch out

Motor wires

Managed to snap the corner of the PCB off. The internals were still ok though, so I put a drop of superglue on it to sort that...

There was a cover

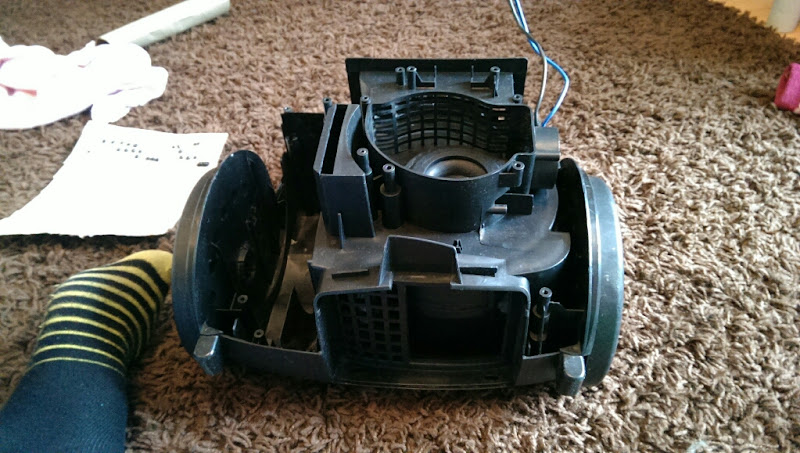

Aha, the top of the motor!

The release valve

4 more screws and the motor housing pulls up, and the motor falls out

This bung held the wiring in

Sound deadening

Pulled it out for washing

2 anti vibration bungs were on the bottom of the motor housing

The beast of a motor is removed (horrible chinese screamer..)

Front wheel was removed

I tried to remove the rear wheels, but couldnt, so they stayed on

Dirtbin next

The ruined filters were removed

There's no washing this. It's the inefficiency of the cyclone system sadly

Bottom flap removed

Cyclone shroud removed

4 screws remove the top shell

2 more blingy bits are removed

This chap here ensures the cyclone cant go back on (without a flatblade screwdriver) without the filters in place

The release clip pops out with a bend of the housing

The only rubber seal on the whole machine that is removeable

and the cyclone was removed!

Onto the tools now. The handle had a tool holder on, I didnt get any tools with this machine, and the random dyson ones I've got for the machine dont fit on it, so I binned it off

Floortool next

50/50 of the brush

Much better!

at the back was a rubber squeezee, which pulls out

Pedal snaps out

and with the wheels removed the neck seperates from the main head

All ready for washing!

All the screws

and all the washed parts!

Floortool first

even cleaner brush strip

and the floortool is done

Cyclone next

cyclone holding clip refitted

and fitted to the lid

plunger refitted

Blingy shiz fitted

rubber seal fitted

shroud fitted

bottom flap fitted

and the cyclone is done

centre wheel fitted

le motor

rubber bungs fitted

Sound deadening fitted

motor located in the bucket

and fitted into the outer housing

wiring bung ready to go

lower sound deadening fitted

with a surprising amount of faffing the two peices were bought together, with everything wanting to fall out at once...

release valve back together

and fitted. Fitted the top suction channel cover too

The airflow check pcb was fitted (was looking for a pipe that connects to it for a while...

the motor was wired up

switch was bought back in

and the cord rewind was connected up and fitted into the housing

lower housing done, it was time for the top

top handle fitted

hose entry housing refitted

blingy bits fitted

pedals were refitted

speed control bits fitted

had to fit the pcb to make sure both the knob and board were at the same place (forgot to time it up before removing, this is what puts me off doing a cambelt on a car...)

little boards fitted

roller fitted

plugged back in

top housing was screwed back down, and with the aid of a screwdriver the cyclone was fitted!

it looks like a trainer (shoe)

It works, but I almost thought it was broken as the suction was no better than a 400w dirty fan Turbopower 1 through the tools, before realising that the pre motor filter needed to be fitted to bridge the gap between motor housing and dustbin.

Filters are ordered, and the conclusion to this thread will be done when they arrive!

Tidied the shed up today too to make use of the space given by these two vacs not being in it anymore!