A few months ago, one of our team managers mentioned that her dyson hose had broken, so she bought a new one...

Fast forward to last thursday, and she told me it was in the back of her car. When she left, I popped with her and grabbed it

Older Dysons came in 2 flavours, Clutched, and Non Clutched.

Non clutched looks like this

And clutched models look like this

If you have a clutch in front of you, you want this thread:

https://manchestervacs.co.uk/DysonForum/index.php/topic,1553.0.htmlAnyway, I bought this dyson into the office as I had an hour left (everyones used to me and vacuum cleaners so not an eyelid was batted...)

and took it home

It was surprisingly non faded! Tayyab tells me it's a later one, due to the lack of stickers on the cyclone, the lime green handle top, lack of wand cap spring and that the plastics are different being a later one so no fading like the earlier models!

Cyclone off first, and put to one side

Cord off

Wand off

Ah yea, forgot about the broken hose

Had a crevice tool

To remove the hose, grab your trusty flatblade, and push in and up on this tab

Which will pop the hose out

Now you can remove the hose, and in my case, sling it in the bin. Put to one side, or run it through the washing machine on a long hot wash with a few towels and the washable filter that sits in the top of the cyclone.

Onto the wand. The wand cap pulls off from one side then falls off

On most other DC04's there is a metal spring here that clips into 2 tiny holes either side of the wand. Remove this if you have it

Around to the front, and lever off one side of the wand release button

and remove it

Pop the spring to one side.

This next bit I almost advise you DO NOT DO, as the risk of borkage is high, and these wand caps are blummin expensive and rare now... but it does lever out from the back

and then lifts off from the front (dont pull it off)

Again, not really needed but I'll cover it for completeness, if you pop this cap off the top cord hook

and undo the large torx screw that sits under the lithium grease

You get the top cord hook off

This photo came out blurry which was a shame but the wand is now complete!

Next, you need to obtain a lovely DC04 Switch removal tool (

https://manchestervacs.co.uk/Dyson/DC04-spares.html/DC04-switch-removal-tool

It can be a b :censored:d, not gonna lie, but it will come out!

You can now remove the screw holding the switch assembly in place

and the switch assembly lifts out

You could strip this part out as well, but they do break easily when removing the switch so I never do anymore. All you need to do is disconnect the neutral wire

Then remove the one live connector from the switch

Unclip the wires from the switch housing

and you should be free

Cable off!

You will need to remove the spade terminal cover off the live wire (no idea why the neutral is showing, sorry!) to get the spine cable out. It does pop out by inserting the switch removal driver into the back of the connector and levering up the locking tab, it locks on the non flat side of the terminal.

Remove the chassis seals

Moving down the machine, pop the post motor filter cover off using the handy lug for just this purpose!

This allows access to the post motor filter

Which really SHOULD NOT be this black!

Next up is the LH Blockage removal assembly. Squeeze both tabs in

and out it comes

To remove the lower part, you hold it like so, the opposite sides to the locking tabs

then squeeze and pull and it will distort away from the tabs and pull off

This then allows you to strip it down as so, the rubber seal pulls off the end of the lower housing

Remove the chassis seal

The seal is held on by a big plastic circlip

This pulls off

Moving underneath the machine, remove the lower blockage removal assembly (this unblocks the wand if you block it via the hose...)

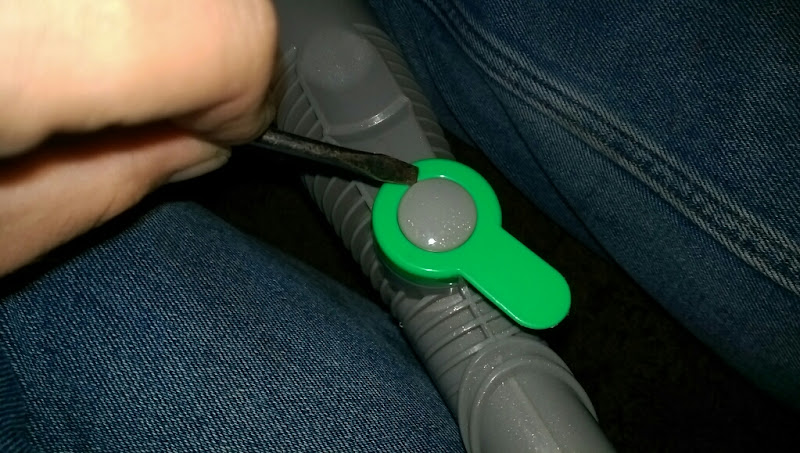

A quick twist of the green part removes it from the u bend if you are being anal about it...

Next is the base plate, and you need to have the machine in this position to start with

because once the locking tabs are undone the base plate comes away like so, and clearance is needed

The base plate lifts away now

There are 2 seals on the baseplate. They may be quite fragile nowadays, and you must not loose them. They do lift out if needed, or can stay in and not harm anyone.

Remove the blockage if you spot one

You will now see the belt winking at you. Pop it off the motor spindle with a screwdriver or your finger

The brushroll lifts out of the housing now

The end caps can be removed now. If you hold both ends and twist/pull, one end will come off. Withdraw the axle and remaining end cap, hold the axle in a vice/molegrips and twist the other end cap off

The bearings sit inside the brushroll

Insert the axle just into the bearing enough so it doesnt come too far out the other side and lever

Damn flash flare, sorry

And out

This brushroll has the common wear on one side, with the other side fine

You could look at replacing it (

https://manchestervacs.co.uk/Dyson/DC04-spares.html/brushroll-non-clutch-dc04-dc07-dc14) but it does sound fine when back together, with no vibrations, and the overall brushroll is good. You'll have to make the call.

Now, back underneath and pull the little hose off the machine. The hose may come away from the grey end, pull the grey end off as well.

Now, very carefully rotate the brushroll housing around and lever it out of either end with something, being careful not to snap the locating tabs on the main cleaner housing

The internal hose unscrews from the brushroll housing, and needs to go in here

Now, get yer flatblade out and pop an edge of these locking circlips up

and remove it

Do the same on the other side

Lay the cleaner like so, then raise it slightly so the head flops down even further still. Whislt still in this position, you need to grab each edge by where it pivots

at the same time and it lifts off

Next, we need to work on the changeover valve. Start by popping the 2 small tabs holding the locking part in place

Push in and down and it moves the part away so it doesnt pop back in. Pull it out from underneath with your fingers

This bit is fun... Whilst gently pulling the top part away from the chassis, push up slightly underneath the black part so there's a gap enough for you to get the screwdriver in each end. Pop the tabs up gently

The black part should lift up once the grey part is clear of the chassis, but then get stuck. Slide the grey part out from the front, then wriggle the black part out, it will catch on the seal underneath

Pull the seal off the diverter valve, this is where the wand blockage u bend connects to

Either side of the chassis, where we pulled the front head off are 2 black locating rings. They pull out easily